The downstream process development team has experience in developing different types of biological macromolecules, and can undertake more than 5 process development (including post process optimization) and 2 or more process characterization projects annually. The team members have a master's degree or above, and have an average of more than 5 years of upstream related work. They have accumulated process development experience in over 20 projects.

The downstream process development laboratory is equipped with 4 AKTA avant chromatography systems and 1 Merck Cogent μ The Scale ultrafiltration system, equipped with various laboratory specifications of chromatography columns, turbidity meters, trace ultraviolet spectrophotometers and other detection equipment, can provide customers with services such as sample preparation and purification process development at different stages.

Service scope

1. Service Case 1

1.1 Background

Process development of dual antibody project

1.2 Challenges

The project timeline is tight, and the expressed protein fragments and aggregates are high in content

1.3 Solution/Results

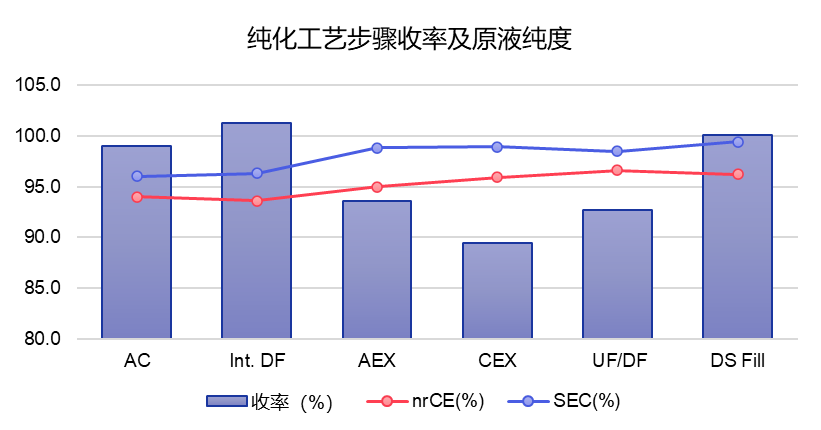

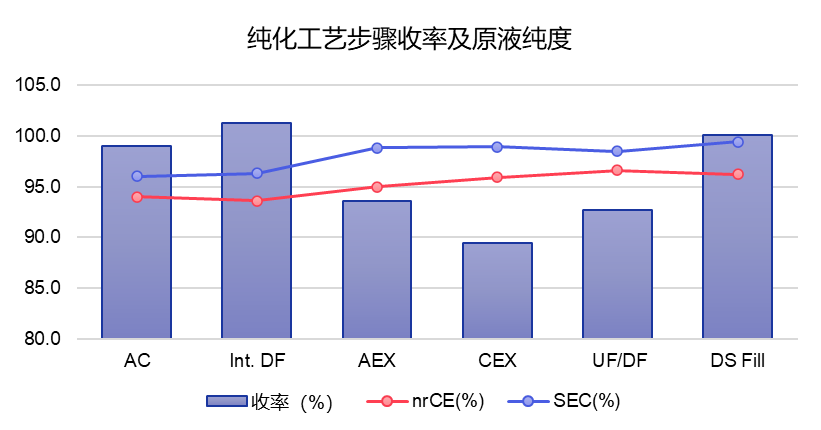

①Three step chromatography is used for process development, and composite mode filler is used for impurity removal

②Process confirmation results: When the SEC purity of the original solution is above 98% and the nrCE purity is above 96%, the total downstream recovery rate is about 73%, and the effective filtration of the target molecule can reach 80%.

2. Service Case 2

2.1 Background

Process optimization in the later stage of clinical phase II project

2.2 Challenges

Replace the chromatography medium when the product quality is consistent, and ensure the robustness of the process performance

2.3 Solutions/Results

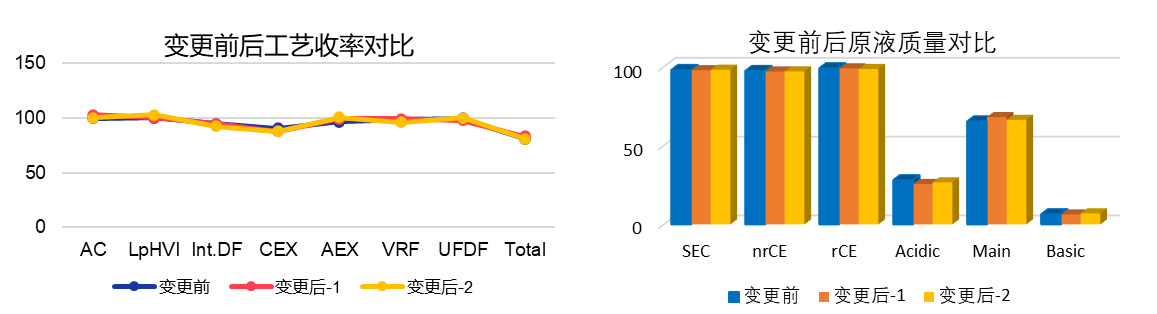

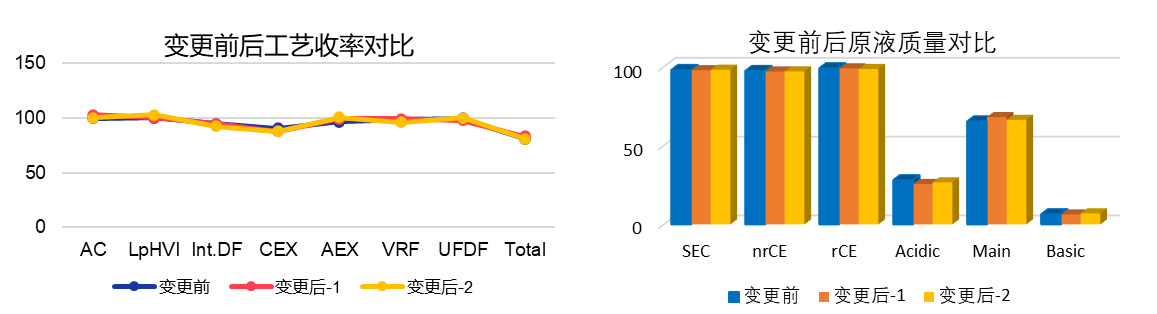

Sort out historical process development reports and determine the main direction for later process optimization

By replacing imported fillers with domestic fillers, the optimized yield and product quality of each process step are consistent with the original process. The filler can be reduced by about 40%, greatly reducing the production of CoGs.

Home

>

Business

>

Tarlead

>

Downstream process development

Home

>

Business

>

Tarlead

>

Downstream process development